Graphite felt for flow battery electrodes

Product Description This product is a specialized graphite felt electrode material for flow batteries, processed using different treatment processes according to the varying performance requirements of different flow battery electrodes. The basic processes include: non-woven needle punching, carbonization, graphitization, and fiber surface post-treatment. This product features a flat felt body, uniform thickness, and consistent electrochemical performance throughout. It is currently widely used in vanadium flow battery electrode materials, zinc-bromine flow battery electrode materials, and zinc-air (zinc-oxygen flow battery electrode materials). It has characteristics such as low internal resistance in the stack, good and uniform electrochemical activity, excellent corrosion resistance, low cycle degradation in the stack, and high energy efficiency.

Key words:

Classification:

Product description

1. Product Description

This product is a special graphite felt electrode material for flow batteries, processed using different treatment processes according to the different performance requirements of various flow batteries for electrode graphite felt. The basic processes include: non-woven needle punching, carbonization, graphitization, and fiber surface post-treatment. This product features a flat felt body, uniform thickness, and consistent electrochemical performance throughout. It is currently widely used in vanadium flow battery electrode materials, zinc-bromine flow battery electrode materials, and zinc-air (zinc-oxygen flow battery electrode materials), with characteristics such as low internal resistance of the stack, good and uniform electrochemical activity, good corrosion resistance, low cycle decay of the stack, and high energy efficiency.

2. Specifications and Models

| Regular Sizes | ||

| Width (m) | 1.42/1.45 | |

| Thickness (mm) | 1.6/2.2/2.5/3.0/3.5/4.0/4.2/4.35/4.6/4.8/5.0/5.6/6.4/7.0 | |

| Others | Cut according to customer requirements | |

3. Technical Indicators and Parameters

| Carbon Content / % | >99 |

| Ash Content / % | <0.3 |

| Bulk Density / (g/cm³) | 0.08-0.11 |

| Specific Surface Area / (m²/g) | 2.3-4 |

| Felt Shedding Rate / (g/gram felt) | 2-3 |

| Oxidation Rate / (weight loss/hour @600℃ in air) | ≤3% |

| Porosity / % | 90-95 |

| Surface Resistance / (Ω/cm²) | <0.15 |

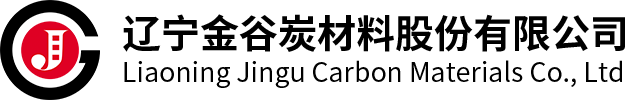

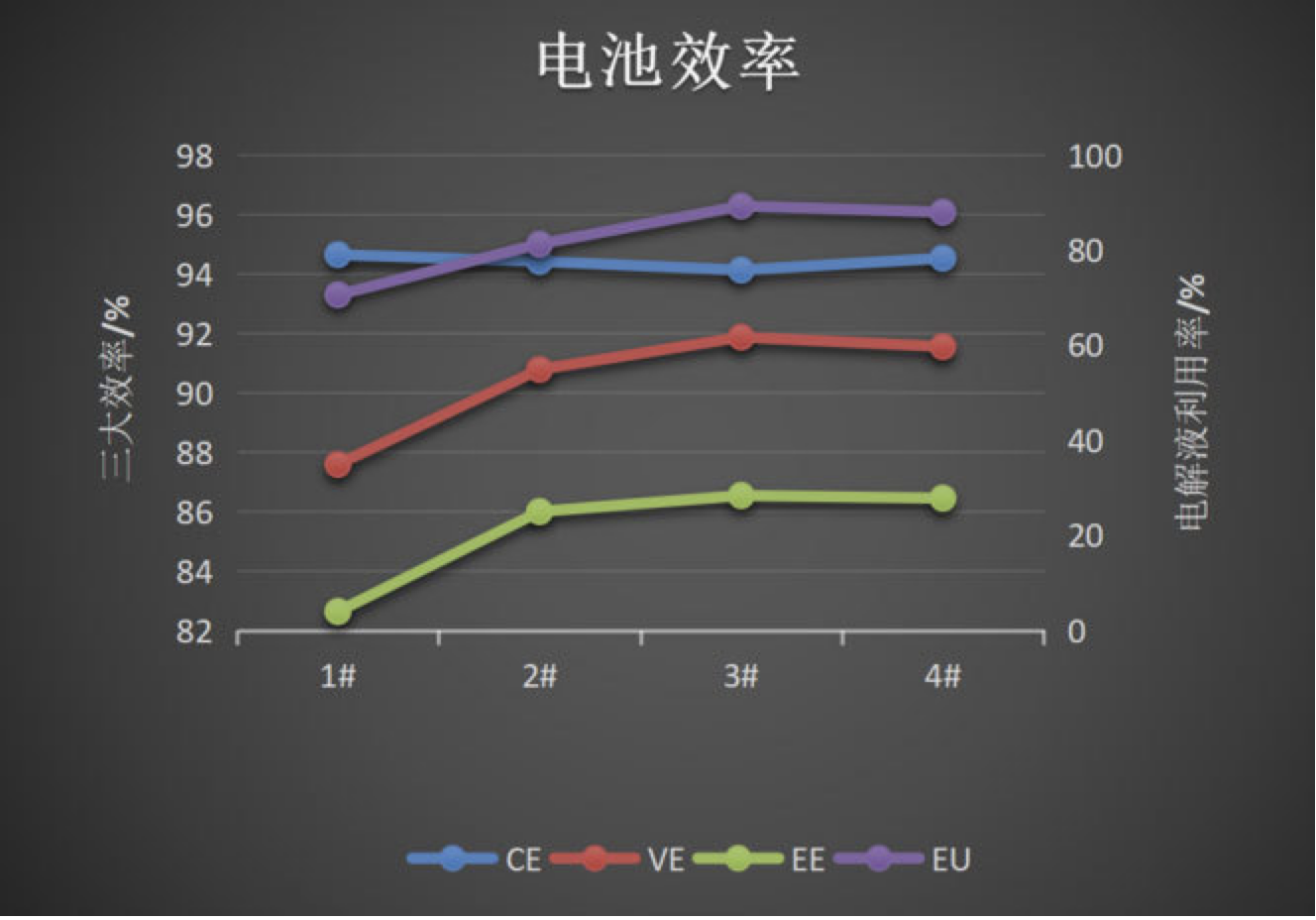

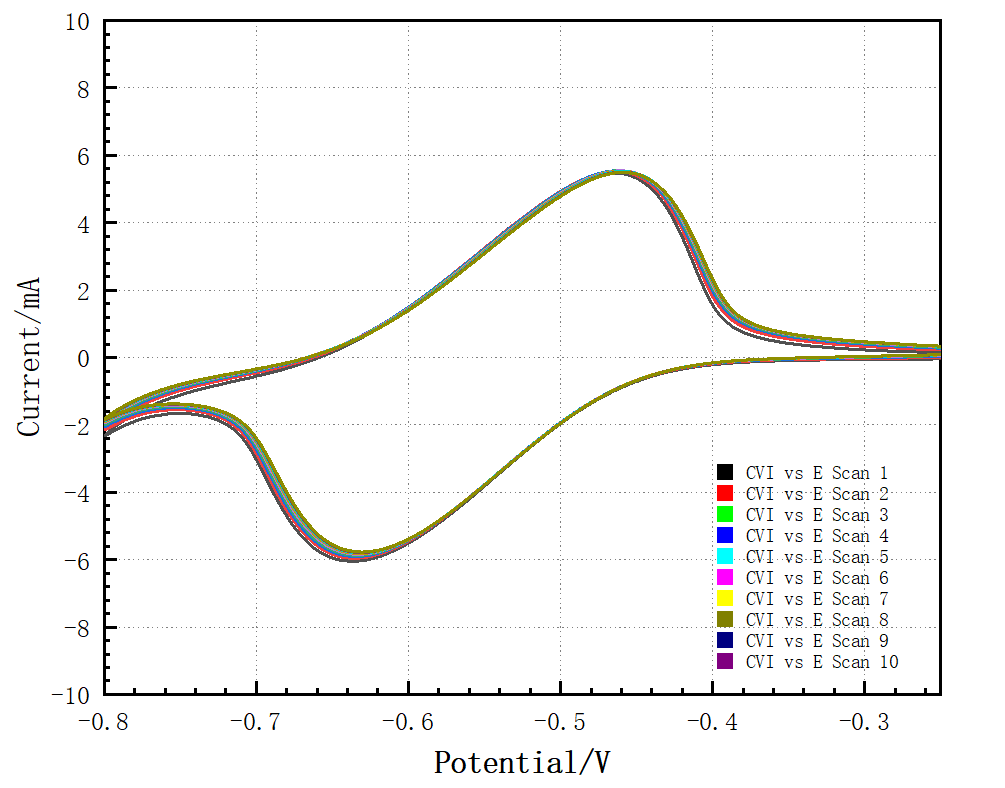

4. Vanadium Flow Battery Performance Curve

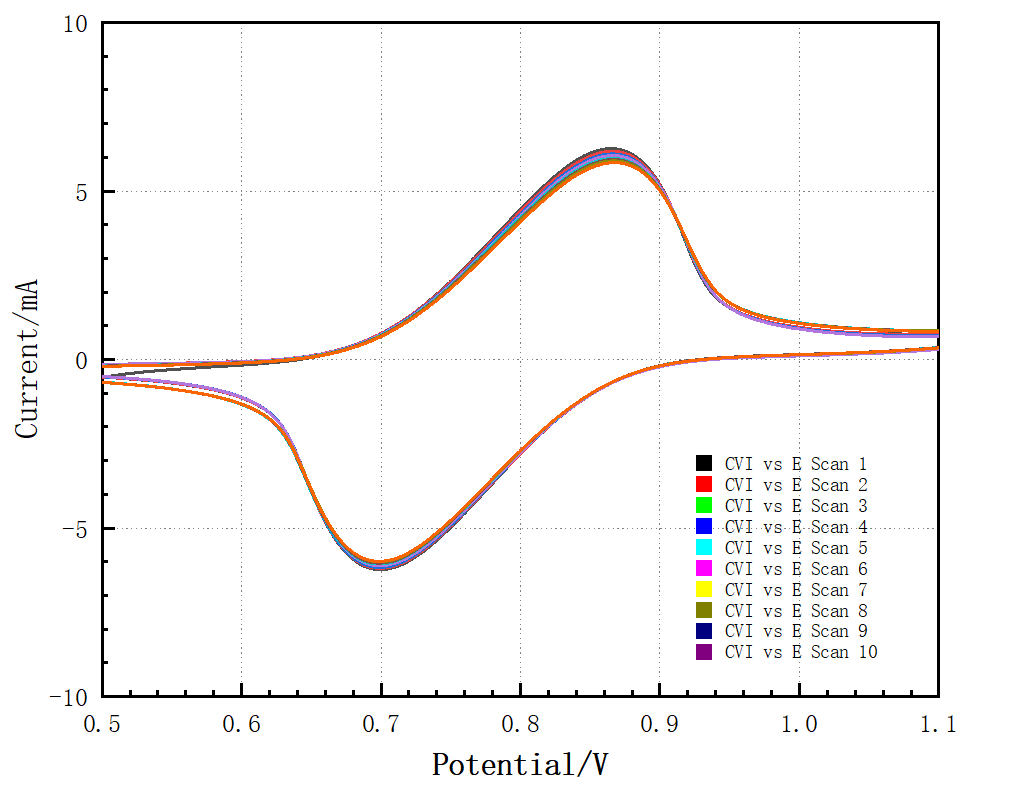

5. Exploration of Activation Mechanism

Positive Electrode Curve

Positive Electrode Curve

Negative Electrode Curve

Negative Electrode Curve

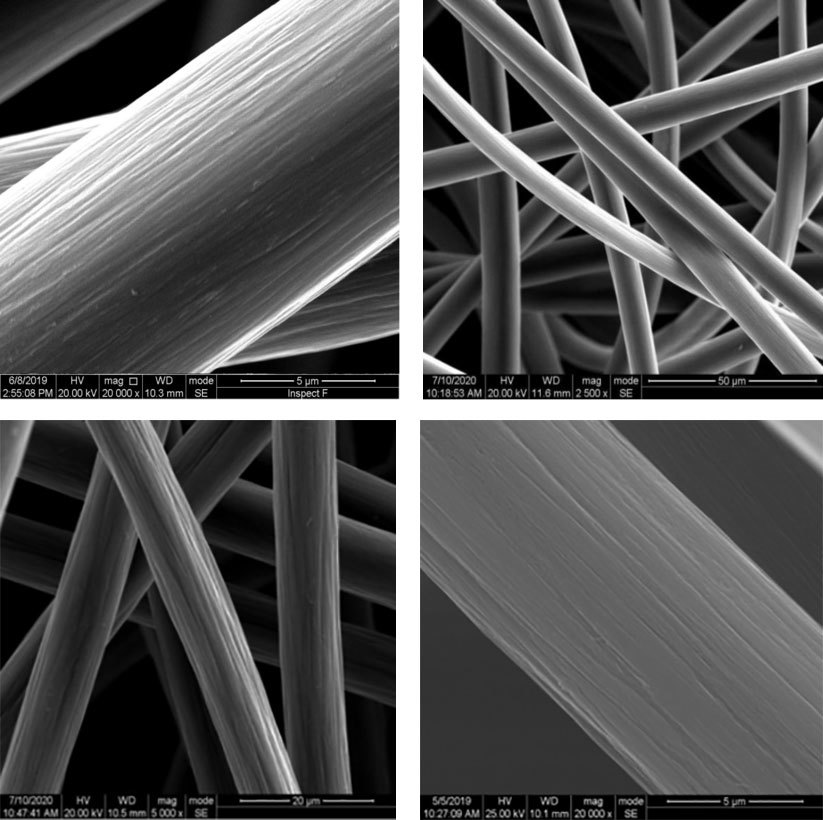

6. Electron Microscopy Images of Electrode Graphite Felt for Batteries

7. Professional Team and Technical Support

Our company has a complete vanadium battery testing system. The testing instruments simulate the working principles of large battery energy storage devices to test the performance of graphitized battery felt. At the same time, further modification of the graphite improves its energy efficiency. Under a current density of 100mA/cm², the energy efficiency is greater than 85%; at 120mA/cm², it is greater than 84%; at 160mA/cm², it is greater than 82%。The main technical parameters include coulombic efficiency, energy efficiency, and voltage efficiency.

8. Packaging and Transportation

Packaging: Woven bag packaging

Transportation Method: Road logistics or express delivery

9. Precautions

Do not apply heavy pressure during transportation and storage, keep it moisture-proof, and it can be cut as needed.

Related Product Cases

Welcome to leave a message for consultation

We will contact you within one working day. Please pay attention to your email.